Why Glove Fit Matters for Safety and Comfort: Essentials

Understanding the Importance of Proper Glove Fit for Safety

What Key Factors Influence Glove Sizing Across UK Workplaces?

Why Glove Fit Matters for Safety and Comfort: In the UK, the significance of ensuring a proper glove fit cannot be overstated, especially in environments where manual tasks are the norm. Achieving the correct glove size is essential for minimising hand strain and maximising performance. The British Standard EN 420 outlines guidelines to help employers select gloves that enhance grip while providing superior protection. Adhering to these standards is critical, as it aligns with health and safety regulations governing workplace safety and employee well-being.

Several factors influence glove sizing, including hand anatomy, the tasks performed, and the materials used in construction. Gloves must accommodate the unique shapes and sizes of hands to avert discomfort or accidents during tasks. The most common glove sizes in the UK typically comprise:

- Small (S)

- Medium (M)

- Large (L)

- X-Large (XL)

- XX-Large (XXL)

Employers must ensure their workforce is equipped with properly fitting gloves, as this practice significantly reduces the risk of workplace injuries and enhances productivity. Without proper sizing, even the most advanced gloves may fail to provide the necessary protection, undermining their intended purpose.

Why Is Material Selection Crucial for Achieving the Perfect Fit?

The selection of materials is critical to achieving an appropriate glove fit, particularly under UK regulations. Workers in sectors such as manufacturing must wear gloves that are not only resilient but also breathable. This feature prevents perspiration from causing slippage, a condition that can significantly compromise comfort and safety. Choosing the right materials is vital to maintaining a secure grip, which is often necessary in high-pressure environments.

Employers should prioritise materials that offer both flexibility and support. For example, gloves made from lightweight yet durable fabrics such as nylon, latex, or nitrile provide comfort without compromising protection. These materials also facilitate breathability, which is particularly essential in sectors where employees may need to wear gloves for prolonged periods. Inadequate material selection can create safety issues, as workers may experience discomfort or reduced dexterity, thereby increasing the likelihood of accidents.

Adopting a knowledgeable approach to material selection not only aligns with UK standards but also fosters a comprehensive culture of workplace safety. Employers must consult safety specialists to identify the most appropriate materials tailored to specific task requirements.

How Does Glove Fit Influence Daily Tasks and Productivity?

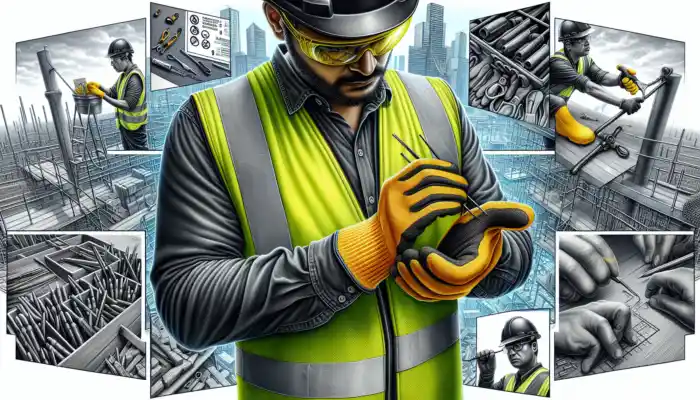

The fit of gloves has a profound impact on daily operations across multiple sectors, particularly in construction and manufacturing, where both dexterity and comfort are crucial. Ensuring that gloves mould effectively to the worker’s hands, as stipulated by UK health guidelines, can significantly reduce fatigue. A well-fitted glove enables superior manipulation of tools and materials, which is essential for maintaining both productivity and safety on site.

When gloves fit properly, workers experience reduced hand strain, enabling them to perform tasks more efficiently. This is especially important in construction, where the use of power tools and heavy machinery demands precision and control. In fields such as healthcare, where dexterity is vital for intricate tasks like surgical procedures, glove fit is paramount. Gloves that conform well to the hands facilitate fine motor skills, improving performance while simultaneously reducing the risk of errors or accidents.

Enhancing glove fit, therefore, has extensive implications for both efficiency and safety. Employers should proactively assess glove fit as part of their health and safety protocols, ensuring all employees are equipped with the correct sizes and styles for their roles. This proactive strategy not only boosts worker confidence but also contributes to a safer working environment.

How Does Poor Glove Fit Compromise Safety?

Why Do Ill-Fitting Gloves Create Workplace Hazards?

Ill-fitting gloves pose significant hazards in the workplace, particularly in factories and construction sites. Loose gloves can significantly reduce dexterity, making it difficult for workers to handle tools and materials effectively. This lack of control elevates the risk of accidents, as workers struggle to grip items securely. In the UK, where safety regulations are stringent, the consequences of using gloves that do not fit correctly can be severe, leading to injuries that could have been easily avoided.

Moreover, the perception of safety can be adversely affected by ill-fitting gloves. Workers who lack confidence in their personal protective equipment may be less inclined to engage in their tasks fully, increasing the likelihood of accidents due to hesitation or distractions. The repercussions extend beyond immediate safety concerns; they can also affect morale and productivity, ultimately resulting in financial costs for businesses.

Employers must take proactive measures to ensure gloves fit well, including conducting regular assessments and providing training on the importance of appropriate PPE (Personal Protective Equipment). By prioritising glove fit, businesses can substantially mitigate hazards and foster a safer, more efficient workplace.

Effects on Hand Protection Standards and Compliance

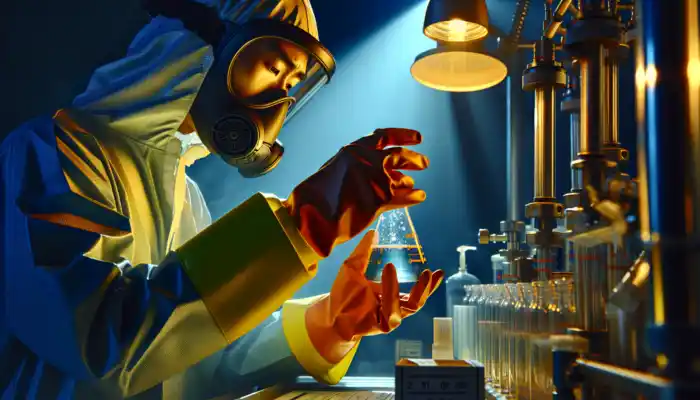

In the UK, adherence to hand protection standards is vital for ensuring worker safety across various industries. Oversized gloves can significantly compromise barrier integrity, leaving workers vulnerable to harmful substances and heightening the risk of injuries. For instance, in laboratory settings, ill-fitting gloves may permit chemicals to seep through gaps, posing serious health risks to employees.

The Health and Safety Executive (HSE) has established specific requirements for gloves designed to protect against chemical exposure, making it essential for employers to provide gloves that adhere to these standards. Gloves that do not fit properly undermine their effectiveness, resulting in non-compliance with safety regulations and potential legal ramifications.

Implementing a rigorous glove fit policy aligns with best practices for workplace safety. Employers must ensure that all gloves are tested and certified for the particular hazards they are intended to mitigate, reinforcing the critical role of fit in meeting these standards. Regular audits and training sessions can further enhance compliance by ensuring all workers understand the importance of proper glove fit.

What Common Mistakes Occur During Fit Assessment?

Fit assessment is a vital component of ensuring workplace safety. Yet many UK workers overlook this step, leading to blisters and tears during use. A common mistake is assuming one size fits all; however, hand sizes and shapes vary widely among individuals, requiring a comprehensive fit assessment for each employee.

Employers must educate their workforce on the importance of conducting fit checks before use. This includes accurately measuring hand size and selecting gloves that provide a snug fit without being overly tight. Regular training and reminders can significantly decrease the likelihood of fit-related injuries, ultimately fostering a safer workplace.

Furthermore, soliciting employee feedback on glove comfort and fit can improve selection processes. When workers feel their needs are acknowledged, they are more likely to engage with safety protocols, resulting in fewer injuries and a more productive environment.

What Dangers Do Oversized Protective Gear Pose in Various Settings?

In diverse settings, including construction and manufacturing, oversized protective gear presents serious dangers that can lead to accidents. For example, oversized gloves can slip during tasks, reducing control over tools and machinery. This situation poses risks not only to the wearer but also to nearby colleagues. In the UK, where the construction industry is under intense scrutiny for safety standards, the use of ill-fitting protective gear can attract regulatory scrutiny and penalties.

In addition, oversized helmets can obstruct vision or shift during movement, which may lead to falls or other unfortunate incidents. It is imperative to acknowledge that the effectiveness of personal protective equipment is heavily reliant on fit. This underscores the need for employers to invest in high-quality fittings and regular assessments to ensure that all protective gear, including gloves, helmets, and other apparel, is appropriately fitted to each worker.

Fostering a culture of safety that prioritises proper fit can yield lasting advantages. By proactively addressing these concerns, employers can establish an environment where safety becomes the norm, significantly reducing the likelihood of accidents and injuries.

What Are the Long-Term Health Effects of Wearing Improperly Fitted Gear?

Consistently wearing ill-fitting safety apparel can have detrimental long-term effects on worker health, particularly in industries such as manufacturing, where tasks are repetitive. For example, improperly fitted gloves can lead to musculoskeletal disorders that develop over time due to unrelieved stress and strain on the hands and wrists. In the UK, employers are legally obligated to assess workplace conditions and provide appropriate PPE that meets health standards, including ergonomic considerations.

Failure to address fit issues can lead to chronic pain and discomfort, affecting not only the individual worker’s quality of life but also broader workplace productivity. Employees suffering from ongoing discomfort may require medical attention, leading to increased absenteeism and associated costs for businesses.

To mitigate these risks, employers should conduct regular glove-fit assessments and provide training on selecting the appropriate size. Moreover, implementing regular ergonomic evaluations can help identify potential issues before they escalate. By prioritising worker health through proper fit, organisations can enhance overall productivity and cultivate a safer, more sustainable workplace.

Expert Recommendations on the Importance of Glove Fit for Safety and Comfort

What Actionable Steps Can Be Taken for Optimal Glove Fit?

Achieving the optimal glove fit involves a series of actionable steps that align with UK-specific fitting techniques. Employers should start by conducting comprehensive assessments of each employee’s hand size and shape, utilising calibrated measuring tools to ensure precision. The Health and Safety Executive’s guidelines provide a valuable framework for selecting sizes based on the unique demands of different roles.

One effective approach is to involve employees in the fitting process. When workers have the opportunity to try on gloves before selection, they can evaluate comfort and mobility and provide feedback on fit and feel. This practice not only enhances safety but also cultivates a sense of ownership over their protective gear. In sectors such as construction, where dexterity is crucial, empowering workers to choose gloves that suit their comfort preferences can significantly improve safety and efficiency.

Additionally, regular training sessions on the importance of glove fit can help sustain awareness among workers. These sessions should address common fit issues and offer strategies for identifying the appropriate gloves for specific tasks. By implementing these proactive measures, businesses can substantially strengthen their safety protocols and ensure workers feel supported in their roles.

What Key Considerations Enhance Comfort Levels in Glove Fit?

Enhancing comfort is a critical aspect of glove fit, especially in the UK, where many workers are required to wear gloves for extended periods. Experts recommend that ergonomic designs can alleviate pressure points and provide greater flexibility, essential for minimising fatigue during long shifts. When protective gear is crafted with comfort in mind, it can lead to increased worker satisfaction and productivity.

Employers should consider materials that offer both comfort and protection. For instance, gloves made from breathable fabrics can help regulate temperature and moisture, preventing discomfort during use. Furthermore, gloves with features such as cushioned palms or articulated fingers can significantly improve comfort, enabling workers to perform tasks with ease.

Regular employee feedback on comfort and performance can yield valuable insights into the effectiveness of specific glove models. Employers should remain open to exploring new materials and designs, ensuring they select the most suitable options for their workforce. By prioritising comfort, businesses can enhance morale and decrease the incidence of fit-related complaints.

How Does Proper Fit Help Prevent Long-Term Health Issues?

The role of glove fit in preventing long-term health issues is underscored by expert insights that align with UK occupational health standards. An accurate fit can significantly reduce the risk of repetitive strain injuries, which are prevalent in sectors requiring continuous hand movements. By investing in high-quality gloves that fit appropriately, employers can demonstrate a commitment to the long-term welfare of their workers.

Instructing employees on the importance of regularly assessing glove fit is essential. Hands can change over time, and what may have been a suitable fit at one point could become inadequate with prolonged use. Establishing a routine check-up system in which workers evaluate their glove fit every few months can help prevent future health problems.

Additionally, integrating ergonomic assessments within the workplace can provide further layers of protection. Employers should contemplate collaborating with workplace health professionals to monitor and evaluate the impacts of glove fit on overall employee health. This proactive approach can significantly reduce long-term health issues and contribute to a more productive work environment.

What Comfort Levels Are Achieved Through Proper Glove Fit?

How Does Glove Fit Enhance Dexterity?

Proper glove fit significantly enhances dexterity, a crucial requirement for workers performing precision tasks, particularly in healthcare settings. Well-fitted gloves improve movement, enabling practitioners to perform delicate procedures without compromising control. This enhancement is especially vital in surgeries and other intricate medical procedures, where even minor errors can have serious consequences.

Beyond healthcare, industries such as electronics assembly also benefit from gloves that deliver a snug fit. Workers can manipulate small components more easily, resulting in fewer mistakes and less material waste. The connection between glove fit and dexterity is evident. When gloves conform to the shape and movements of the hand, they allow a full range of motion, thereby enhancing performance across various tasks.

Employers should prioritise glove fit in their procurement processes to ensure their workforce has access to gloves that promote dexterity. This approach will not only improve task outcomes but also enhance overall worker satisfaction and safety.

Why Does Comfort Matter During Extended Wear?

In settings such as agriculture, where workers often don gloves for prolonged periods, comfort becomes an essential consideration. Proper fit enhances circulation, preventing fatigue and discomfort during long shifts. Gloves that are either too tight or too loose can cause complications, including reduced blood flow, numbness, and cramping, all of which can significantly impair a worker’s ability to perform effectively.

Employers must focus on providing gloves that not only fit well but also incorporate features specifically designed for extended wear. These may include moisture-wicking materials, cushioned palms, and ergonomic designs that conform to the natural shape of the hand. By investing in high-quality gloves, businesses can ensure that their workers remain comfortable and productive throughout their shifts.

The psychological impact of comfort should not be underestimated; when workers feel comfortable in their gear, they are more likely to be engaged and motivated in their tasks. This ultimately contributes to a more positive workplace atmosphere, cultivating higher levels of productivity and satisfaction.

How Does Proper Fit Influence User Satisfaction Rates?

Gloves that fit correctly directly impact user satisfaction, especially in the UK, where industry feedback frequently emphasises the importance of comfort and functionality. When gloves provide a snug, secure fit, workers report greater comfort, which in turn boosts morale and a more positive attitude toward their tasks. This correlation is observed across sectors, as a proper fit enhances both confidence and performance.

Understanding specific comfort metrics can help employers assess the effectiveness of glove fit within their workforce. Key metrics may include:

- Reduced hand fatigue

- Fewer complaints about discomfort

- Increased grip strength

- Enhanced overall productivity

By monitoring these metrics, businesses can make informed decisions regarding glove procurement and training. Furthermore, fostering open communication about comfort levels can lead to continuous improvements and adaptations that better meet workers’ needs.

Ultimately, prioritising fit and comfort is a strategic approach that benefits both workers and employers alike. Higher user satisfaction rates can translate into lower turnover and greater loyalty, contributing to a more stable and effective workforce.

How Does Proper Fit Enhance Safety in Hazardous Environments?

In hazardous environments, such as manufacturing and chemical handling, the importance of proper glove fit cannot be overstated. Well-fitted gloves prevent slippage, which is essential for maintaining dexterity and control when handling potentially hazardous materials. A secure fit also maximises exposure protection, minimising the risk of chemical burns or injuries.

For instance, in manufacturing, properly fitting gloves can prevent accidents related to machinery, where loose gear may become caught or interfere with operational tasks. In this context, employers must ensure that all gloves meet the specific safety criteria requisite for the tasks at hand.

Ongoing training and safety evaluations reinforce the link between glove fit and workplace safety. Employers should conduct regular assessments of glove performance in hazardous environments to ascertain if their current standards are adequate. By prioritising glove fit, organisations can significantly reduce the risk of accidents, contributing to long-term occupational health and safety.

Research-Backed Advantages of Why Glove Fit Is Essential for Safety and Comfort

How Does Research Support Safety Enhancements?

Research conducted in the UK indicates a compelling link between accurate glove fit and lower accident rates in manufacturing. Studies show that when workers wear correctly fitted gloves, their risk of accidents or injuries decreases markedly. This evidence-based perspective underscores the importance of prioritising glove fit as a fundamental aspect of workplace safety.

By analysing data from local studies, businesses can make informed decisions regarding their glove procurement processes. Employers should consider investing in gloves that meet specific performance standards, as research has confirmed that quality gear correlates directly with improved safety outcomes. The evidence supports the notion that proper glove fit extends beyond mere comfort; it is a critical factor in safeguarding workers from harm.

Employers must stay informed about the latest studies and advancements in glove technology to ensure they provide the highest-quality protective gear for their workforce. This proactive stance can lead to a more informed selection process, ultimately enhancing worker safety.

What Health and Wellbeing Benefits Are Associated with Proper Fit?

The health and wellbeing of employees is a significant consideration for UK businesses, and research indicates that fitted gloves can reduce the incidence of injury claims in office settings. Employees wearing properly fitting gloves are less likely to experience discomfort, fatigue, or injuries from repetitive tasks. This leads to fewer claims and diminished costs associated with workplace injuries.

Implementing effective glove-fit strategies can yield substantial benefits for health and wellbeing, including reduced absenteeism and improved employee morale. When workers feel supported by their employers through the provision of appropriate protective gear, it fosters a positive culture centred on safety and well-being.

Employers should continually review their glove policies and practices to ensure alignment with the latest health and safety regulations. Additionally, promoting a culture of continuous improvement can enhance overall employee satisfaction and wellbeing, ultimately benefiting the organisation as a whole.

What Long-Term Benefits Are Realised in Professional Settings?

The long-term advantages of evidence-based glove fit become apparent in professional settings, particularly in industries where precision and safety are critical. Research shows that improving glove fit not only enhances safety but also sustains gains in job performance. Workers provided with properly fitting gloves can perform their tasks more effectively, resulting in increased productivity and better overall outcomes.

These benefits can be particularly pronounced in fields such as healthcare, where precision is paramount. Studies show that healthcare professionals who wear well-fitted gloves experience fewer interruptions during procedures, leading to better patient outcomes and greater efficiency.

Employers should consider integrating fit assessments into their ongoing training programmes to ensure employees are well-equipped to select the appropriate gloves for their feet. By doing so, businesses can cultivate a culture of safety that emphasises the importance of fit, leading to long-term benefits for both workers and the organisation.

How Does Proper Fit Affect Worker Productivity in Safety-Critical Roles?

The impact of properly fitted gloves on worker productivity in safety-critical roles is profound, as highlighted by UK research. Studies indicate that correctly fitted gloves boost productivity by minimising distractions from discomfort, enabling workers to concentrate entirely on their tasks. This is particularly crucial in high-risk environments, such as construction and manufacturing, where safety and efficiency are paramount.

When employees are free from distractions caused by ill-fitting gear, they can perform at their best, leading to higher output and fewer errors. Employers should regard proper glove fit as a vital investment in their workforce, as it correlates directly with improved productivity metrics.

Regular evaluations of glove fit and comfort in safety-critical roles can help identify areas for improvement. By continuously refining their glove selection and fit processes, employers can create an environment where productivity flourishes, ultimately benefiting the entire organisation.

What Insights Have Comparative Analyses Revealed Between Fitted and Ill-Fitting Gloves?

British studies have undertaken comparative analyses between fitted and ill-fitting gloves, revealing stark contrasts in comfort-related complaints and safety incidents. Research shows that workers who wear correctly fitted gloves report significantly fewer discomfort or mobility issues. This leads to fewer safety incidents, as comfort directly influences performance.

Employers must acknowledge the importance of investing in high-quality gloves that prioritise fit. The evidence indicates that the upfront costs of procuring better-fitting gloves can yield significant savings through reduced injury claims and improved productivity.

Incorporating employee feedback on glove fit can provide valuable insights to guide purchasing decisions. By actively engaging with workers about their experiences, employers can ensure they are selecting the most suitable options for their specific needs, ultimately fostering a safer and more productive workplace.

Why Is Proper Glove Fit Essential Across Various Industries?

What Makes Glove Fit Critical in Manufacturing?

In the manufacturing sector, a precise glove fit is essential for preventing mishaps on assembly lines, where workers handle a variety of materials and machinery. Ill-fitting gloves can pose serious risks, including accidents stemming from reduced dexterity or grip. In the UK, adherence to local safety standards is vital for maintaining a secure working environment.

Employers must ensure employees are equipped with gloves that fit well and comply with safety regulations. This includes selecting gloves specifically designed for the tasks and materials encountered on the job. Regular training on the importance of glove fit can enhance workers’ awareness, leading to better safety outcomes.

Moreover, investing in the appropriate glove fit aligns with best practices in occupational health and contributes to a culture of safety that prioritises the wellbeing of all workers. By reinforcing the connection between glove fit and safety, employers can effectively mitigate risks associated with manufacturing processes.

How Does Glove Fit Affect Emergency Services?

In emergency services, the necessity for snug-fitting gloves is paramount, as they directly influence operational effectiveness. For UK firefighters, well-fitting gloves not only improve grip but also enable better control of equipment in critical situations. Ill-fitting gloves can slow response times and increase risk, ultimately jeopardising the safety of both emergency responders and those they assist.

Training sessions on proper gear fit can reinforce best practices among emergency personnel. By ensuring all gloves fit snugly and are comfortable, emergency services can maintain high operational efficiency, enabling responders to act swiftly and effectively in crises.

Furthermore, the use of properly fitted gloves aligns with UK health and safety regulations, ensuring that all emergency personnel are equipped with the necessary protective gear to perform their duties safely. Employers should continually assess the availability and fit of gloves provided to emergency responders, fostering a culture of preparedness and safety.

What Role Does Glove Fit Play in Agriculture and Outdoor Work?

In agriculture, proper glove fit is crucial for UK farmers handling tools and equipment in varying weather conditions. The right fit is essential for ensuring that workers can manage their tools safely without compromising dexterity. Poorly fitting gloves can hinder movement, increasing the risk of accidents and injuries when handling sharp or heavy equipment.

Employers must consider seasonal adaptations when selecting gloves for agricultural tasks. The types of gloves suitable for winter may differ significantly from those required in summer months. A list of seasonal adaptations may include:

- Insulated gloves for winter tasks

- Water-resistant gloves for wet conditions

- Lightweight gloves for summer use

- Gloves with reinforced palms for enhanced grip

By providing appropriate gloves for different seasons, employers can ensure that workers are prepared to tackle the challenges posed by changing weather conditions. This proactive approach not only enhances safety but also instils a sense of care within the agricultural sector.

Why Is Proper Glove Fit Vital in Healthcare?

In the healthcare industry, proper glove fit is imperative to ensure workers can perform procedures with precision, particularly in hospitals and clinics. The risk of infection is a critical concern, making it essential that gloves fit securely to maintain sterility during surgeries and patient care. Ill-fitting gloves can lead to contamination, jeopardising patient safety and resulting in adverse outcomes.

Healthcare professionals must be equipped with gloves that conform to their hands, enabling fine motor skills and dexterity during critical tasks. Regular training on glove selection and fit is vital for maintaining compliance with safety protocols and providing a high standard of care for patients.

Employers should prioritise procuring gloves that meet healthcare regulations while also prioritising comfort and usability. By investing in well-fitted gloves, healthcare organisations can foster a culture of safety that protects both patients and staff, ultimately improving health outcomes.

What Is the Relevance of Proper Glove Fit in the Food Industry?

In the food sector, an accurate glove fit is essential for food handlers to prevent contamination and safely manage ingredients in kitchens and factories. Compliance with hygiene regulations is critical, and improper glove fit can significantly increase the risk of foodborne illness. In the UK, food safety standards require the use of gloves that fit securely to ensure hygiene and safety during food preparation.

Employers must guarantee that food handlers are equipped with gloves that provide both comfort and protection. This includes selecting gloves made from food-safe, wear-resistant materials. Employees should receive training on the importance of proper glove fit, as it is vital to maintaining hygiene standards.

By prioritising glove fit in the food industry, businesses can enhance compliance with health and safety regulations and reduce the risk of food contamination. This proactive strategy not only safeguards public health but also cultivates a culture of accountability within the industry.

Essential Tips for Ensuring the Right Glove Fit

Why Are Regular Glove-Fit Checks Necessary?

Regular checks of glove fit are essential in the UK, particularly in roles such as engineering, where employees may experience changes in hand size due to various factors. Periodic fit evaluations are crucial for maintaining safety and comfort as we adapt to these changes. Employers should establish a routine for assessing glove fit to ensure all workers are equipped with the appropriate sizes for their specific tasks.

By conducting regular checks, businesses can identify fit issues before they escalate into more significant safety concerns or health problems. This proactive strategy enhances workplace safety and promotes a culture of care where employees feel valued and supported.

Employers should also encourage workers to provide feedback on their glove fit. Open communication channels can yield valuable insights that improve glove selection and contribute to a safer work environment.

What Effective Strategies Can Be Employed for Selecting Gloves?

Selecting gloves effectively in the UK necessitates careful consideration of hand measurements against certified standards. Workers should be encouraged to accurately measure their hands to determine the correct size, ensuring a proper fit that promotes both safety and comfort. This process should be standardised across workplaces, with clear guidelines for measuring hand size and selecting gloves accordingly.

Employers can enhance glove selection processes by providing resources that educate employees on the importance of fit. This may include hands-on training sessions demonstrating how to select appropriate gloves for different tasks, as well as offering a variety of glove options to accommodate diverse hand shapes and sizes.

By implementing effective glove selection strategies, businesses can create a safer work environment that prioritises worker wellbeing while adhering to health and safety regulations.

How Can Fit-Related Complaints Be Effectively Addressed?

Addressing fit-related complaints is crucial to maintaining overall satisfaction among UK workers. Common issues can be resolved through expert consultations, enhancing not only individual comfort but also overall workplace safety. Employers should establish a process for employees to report fit-related concerns, ensuring that these issues are taken seriously and addressed promptly.

By actively engaging employees about their experiences, employers can gather valuable feedback to inform future glove procurement decisions. Additionally, providing workers with access to safety specialists can lead to better fit assessments and greater comfort.

Regularly revisiting glove fit policies and practices is essential for fostering a culture of continuous improvement. By prioritising worker feedback and effectively addressing fit-related complaints, businesses can foster a more positive work environment that enhances both safety and productivity.

Frequently Asked Questions

Why Is Glove Fit Important in the Workplace?

Glove fit is vital in the workplace as it directly influences safety and comfort. Properly fitted gloves enhance dexterity, prevent accidents, and reduce fatigue, ultimately increasing productivity and worker satisfaction.

How Can I Measure My Glove Size Accurately?

To accurately measure your glove size, use a measuring tape to measure the circumference of your hand around the palm, just below the knuckles. Compare this measurement with a glove sizing chart to determine your size.

What Are the Common Materials Used for Gloves?

Common glove materials include latex, nitrile, vinyl, leather, and neoprene. Each material provides different properties, such as flexibility, durability, and chemical resistance, which affect their suitability for various tasks.

How Often Should Glove Fit Checks Be Conducted?

Glove fit checks should be conducted regularly, ideally every few months or when hand size changes are noted. This ensures that workers use gloves that provide optimal safety and comfort at all times.

What Are the Signs of Ill-Fitting Gloves?

Signs of ill-fitting gloves include discomfort, slippage during use, pinching, and reduced dexterity. Workers should report these issues to ensure they are using properly fitted gloves.

Are There Regulations Regarding Glove Fit in the UK?

Yes, the UK has strict regulations regarding glove fit under health and safety laws. Employers must provide gloves that meet specific standards for safety, comfort, and effectiveness in the workplace.

What Industries Require Specific Glove Fit Considerations?

Industries such as manufacturing, healthcare, food service, and construction require specific glove fit considerations due to the unique hazards and tasks associated with each sector.

How Can Employers Ensure Compliance with Glove Fit Standards?

Employers can ensure compliance by conducting regular assessments, providing training on proper glove fit, and selecting high-quality gloves that meet health and safety regulations.

What Are the Long-Term Effects of Wearing Ill-Fitting Gloves?

Long-term effects of wearing ill-fitting gloves can include chronic pain, musculoskeletal disorders, reduced dexterity, and increased risk of workplace injuries. Proper fit is essential to mitigate these health risks.

How Can I Improve Glove Comfort During Long Shifts?

To enhance glove comfort during extended shifts, choose breathable materials, consider ergonomic designs, and regularly assess fit to ensure that your gloves provide adequate support without restricting movement.

Add comment