No products in the cart.

Return To ShopMatching Glove Material To Specific Chemicals Handled

Comprehensive Guide to Glove Materials in the UK

Explore the Most Common Types of Gloves Used Across UK Industries

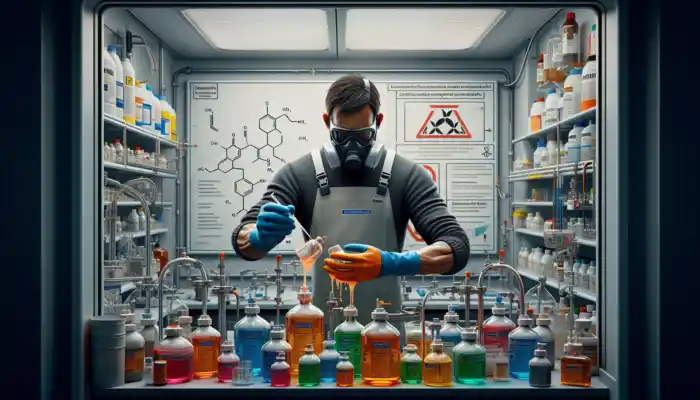

Matching Glove Material to Specific Chemicals Handled: In the UK, various glove materials are used across industries to ensure both safety and compliance, particularly during chemical handling. The most commonly used types include nitrile and latex, which are particularly preferred within the manufacturing and healthcare sectors due to their excellent resistance to oils, acids, and a wide range of chemicals. Nitrile gloves, in particular, are renowned for their durability and effectiveness in providing a substantial barrier against hazardous substances, making them a top choice for numerous workers. Furthermore, these glove materials comply with HSE guidelines, ensuring safe handling practices are consistently upheld in workplaces across Britain. With growing awareness of potential health risks, selecting the right glove types has become crucial for safeguarding worker safety.

What Key Factors Shape the Selection of Glove Materials in the UK?

The process of selecting glove materials in the UK is influenced by a range of factors, with regulations from local authorities such as the HSE playing a central role. It is vital to ensure that glove materials are appropriate for specific chemical exposures to prevent workplace hazards. Considerations such as the chemical’s properties, including its permeability and toxicity, alongside the frequency and duration of exposure, must be thoroughly evaluated. Additionally, local standards and rigorous testing protocols guarantee that the chosen materials maintain their protective qualities and integrity in British environments. This regulatory framework guides employers in making well-informed decisions, ultimately contributing to a safer work environment for all.

What Are the Established Standards for Glove Materials in the UK?

In the UK, stringent standards govern the selection and testing of glove materials to ensure their compatibility with various chemicals. British standards such as BS EN 374 outline the critical criteria for material effectiveness, focusing on local certification and enforcement to protect workers across diverse environments. These standards are not mere recommendations; they are essential for compliance, ensuring that gloves can withstand specific chemical exposures effectively. Key British standards for material testing include:

- BS EN 374-1: General requirements

- BS EN 374-2: Determination of resistance to penetration

- BS EN 374-3: Determination of resistance to permeation

- BS EN 420: General requirements for protective gloves

- BS EN 455: Medical gloves for single use

- BS EN 1186: Materials in contact with food

Understanding these standards is crucial for both manufacturers and employers who aim to guarantee the safety and reliability of the gloves provided to their workers.

How to Effectively Match Glove Materials with Chemicals?

Identifying Chemical Risks in UK Workplaces for Enhanced Safety

Assessing chemical risks in UK workplaces is vital to the effective selection of glove materials. In factories and laboratories, common chemicals range from solvents and oils to acids and alkalis, each presenting unique safety challenges. Matching glove materials based on permeability data plays a crucial role in enhancing protection and ensuring compliance with local regulations. For instance, nitrile gloves are frequently the go-to choice for handling oils, while PVC gloves might be more suitable for specific solvents. Conducting comprehensive risk assessments ensures that workers are equipped with the most appropriate gloves, significantly reducing exposure risks and fostering a safer working environment overall.

What Effective Testing Methods Exist for Evaluating Glove Materials?

Evaluating the performance of glove materials against specific chemicals is essential to ensuring durability and safety in British industrial applications. UK-approved testing methods thoroughly assess how well various glove materials resist chemical penetration and degradation over time. This rigorous testing involves exposing gloves to a variety of chemicals under controlled conditions to determine their ability to maintain protective qualities. The data gathered from these tests is invaluable, guiding the selection process and ensuring that employers choose gloves that serve as effective barriers against the chemicals their teams handle. Proper testing not only identifies potential risks but also strengthens organisations’ overall safety culture.

What Are the Best Pairing Strategies for UK Chemicals?

When pairing glove materials with specific chemicals, several strategies can enhance workplace safety and prolong glove longevity. For example, pairing PVC gloves with solvents is often advantageous because PVC is highly resistant to a wide range of chemicals. Additionally, understanding the specific properties of chemicals, such as viscosity and temperature, is paramount. By utilising UK-specific data, employers can make informed decisions regarding which materials to use, tailored to the unique conditions present in British workplaces. Moreover, careful consideration of exposure duration and the potential for chemical splashes is necessary to ensure that chosen gloves provide sufficient protection while promoting worker safety.

What Key Factors Influence Glove Selection for Chemicals in the UK?

Environmental factors, including temperature and humidity, significantly influence the selection of glove materials in British workplaces. For instance, elevated temperatures can increase perspiration and reduce comfort, potentially compromising the gloves’ effectiveness and heightening the risk of chemical exposure if the gloves degrade more quickly. Furthermore, humidity levels can impact the integrity of specific glove materials, making it crucial to consider these environmental factors alongside chemical compatibility. To optimise glove choice, employers must align their selections with HSE guidelines and best practices, ensuring that both safety and comfort are prioritised in the daily operations of workers handling hazardous materials.

Expert Insights on Effectively Matching Glove Material to Specific Chemicals Handled

What Key Recommendations Do Experts Have for UK Users?

Experts in the field advocate for a systematic approach when UK users select glove materials for chemical handling. Key actionable steps include conducting a thorough risk assessment to identify the specific chemicals being handled and their associated hazards. For instance, a case study from a British chemical plant underscored the importance of matching nitrile gloves with solvent-based adhesives, resulting in a significant reduction in skin irritations among workers. Additionally, gathering worker feedback on glove comfort and effectiveness is crucial for making informed decisions and ensuring practical solutions that enhance chemical safety in the workplace.

What Advanced Material Analysis Techniques Are Available?

Advanced techniques for analysing the permeability ratings of glove materials are essential to ensure safety against specific UK chemicals. Experts recommend using local research data to guide precise matching, as this requires a deep understanding of the chemical interactions that may occur with glove materials over time. Techniques such as gas chromatography and liquid chromatography facilitate detailed analyses of how different materials withstand exposure to chemicals. This comprehensive understanding enables organisations to select gloves that provide superior protection while considering the specific demands of their work environments. Continuous research and feedback loops with manufacturers further enhance material performance and safety.

How to Evaluate Long-Term Material Performance Effectively?

Monitoring the efficacy of gloves over time is critical to ensuring sustained protection against chemicals in British workplaces. Experts suggest implementing regular checks to assess the condition of in-use gloves, as wear and tear can significantly affect their performance. Strategies include establishing a routine for inspecting gloves for visible signs of damage or degradation, particularly following exposure to harmful substances. Maintaining open lines of communication with workers about their experiences with glove performance can yield invaluable insights. Maintenance tips from UK experts include:

- Regularly inspect gloves for any signs of wear.

- Replace gloves immediately if they show signs of damage.

- Store gloves in a cool, dry place to prolong their lifespan.

- Train personnel on proper glove removal techniques to reduce contamination risks.

By implementing these strategies, organisations can enhance safety standards and minimise employee exposure risks.

What Innovations Are Emerging in Glove Materials for UK Chemical Applications?

The landscape of glove materials for chemical applications is continuously evolving, with local innovators pushing the boundaries of what is achievable. Experts highlight advancements in materials such as polyurethane and bio-based polymers, which offer greater flexibility and durability while maintaining high chemical resistance. These innovations are particularly significant for meeting the diverse needs of industries ranging from pharmaceuticals to manufacturing. By incorporating these cutting-edge materials in workplaces, organisations not only elevate safety standards but also align with sustainable practices, reflecting a growing awareness of environmental concerns in chemical handling. Staying updated on these developments ensures organisations maintain high safety standards while adapting to the latest technological advancements.

What Are the Risks of Using Mismatched Gloves in the UK?

Identifying Potential Health Hazards for UK Workers

Using mismatched gloves poses serious health risks for workers in the UK, as improper material selection can lead to severe skin conditions and chemical burns. Exposure to harmful substances due to inadequate glove protection can result in both acute and chronic health issues, highlighting the critical need for proper material matching. Such risks not only threaten individual health but can also lead to broader workplace safety violations and a failure to meet UK health regulations. Organisations must prioritise effective glove matching to mitigate these risks and safeguard their employees’ well-being.

How Do Mismatches Affect Workplace Safety and Compliance?

Inadequate gloves can trigger a cascade of safety concerns within British industries, significantly increasing the likelihood of accidents and injuries. When workers depend on gloves that do not offer sufficient protection, the risk of exposure to harmful chemicals escalates dramatically. This not only jeopardises employee health but can also lead to higher injury rates and violations of local safety codes. Furthermore, such lapses can trigger investigations and potential penalties from health and safety regulators, emphasising the importance of precise glove matching. Cultivating a safety-focused culture that prioritises appropriate glove usage is essential for maintaining compliance and protecting workers.

What Are the Common Errors Made in Material Choice in the UK?

Failing to consider chemical compatibility when selecting gloves can lead to critical failures, as various UK reports have highlighted the consequences of mismatched materials. Such errors often result in enforcement actions from health authorities and can lead to substantial health claims from affected workers. In many cases, employers may opt for gloves for convenience rather than conduct thorough assessments of the chemicals involved. Such oversights can have severe repercussions, including legal liabilities and reputational damage. Therefore, ensuring informed material choices based on compatibility is essential for maintaining workplace safety and regulatory compliance.

Research-Backed Benefits of Matching Glove Material to Specific Chemicals Handled

What Evidence Exists from UK Studies on Material Efficacy?

Research conducted in the UK has consistently shown the tangible benefits of correctly matching glove materials to specific chemicals. Studies indicate a significant reduction in exposure incidents when suitable gloves are employed, underscoring the importance of adhering to compatibility guidelines. For example, trials conducted in controlled laboratory settings showed that workers using appropriately matched gloves experienced substantially fewer skin irritations and chemical exposure incidents than those using mismatched materials. These findings reinforce the vital role that proper glove selection plays in enhancing workplace safety and ensuring compliance with health regulations.

What Trusted Strategies Can Enhance Protection for Workers?

Employers can adopt several trusted strategies to bolster worker protection against chemical exposure. Implementing comprehensive training programmes that educate staff on proper material matching and safe chemical handling techniques is essential. Additionally, conducting regular audits of glove inventories ensures compliance with HSE guidelines and enables timely updates as chemical use evolves. Providing staff with access to data on chemical properties and glove performance empowers them to make well-informed decisions about their personal protective equipment. Ultimately, aligning glove materials with the chemicals they handle not only enhances safety but also fosters a proactive safety culture within organisations.

What Are the Long-Term Advantages of Proper Glove Matching in UK Settings?

The long-term benefits of correctly matching glove materials are evident, with research indicating substantial cost savings and reduced workplace incidents. By investing in high-quality gloves that are appropriately matched to the chemicals in use, organisations can minimise the financial burdens associated with health claims and regulatory penalties. Furthermore, improving safety reduces workplace disruptions, thereby boosting overall productivity. The benefits of investing in suitable materials extend beyond mere compliance, creating a safer work environment that prioritises employee well-being. Key benefits identified in UK research include:

- Reduced risk of chemical exposure incidents.

- Enhanced employee morale and job satisfaction.

- Lower healthcare costs related to workplace injuries.

- Improved regulatory compliance and reduced legal liabilities.

These advantages reinforce the importance of prioritising proper glove matching within the workplace.

Why Is Proper Matching Crucial for UK Workers?

What Role Does Matching Play in Daily Work Tasks?

Correct material selection is paramount for preventing chemical absorption during routine tasks in UK workplaces. Employees rely on the protective qualities of gloves to safeguard their health while complying with national protocols. Without proper matching, workers face heightened exposure risks, leading to severe health consequences. Ensuring that gloves are tailored to the specific chemicals being handled not only fosters compliance but also enhances the overall well-being and productivity of the workforce. The significance of effective glove matching is profound, as it directly influences the efficacy of the safety measures in place.

How Does Proper Matching Impact Regulatory Compliance?

Proper glove matching has a significant impact on regulatory compliance, ensuring organisations meet the legal requirements set by UK health and safety authorities. By selecting gloves that are compatible with the chemicals being handled, employers mitigate the risk of violations and potential fines. This proactive approach not only protects workers but also cultivates a culture of safety within the organisation, reinforcing the importance of adhering to established standards. Compliance with regulations is not solely about avoiding penalties; it signifies a commitment to worker safety and health, fostering trust among employees and stakeholders alike.

What Are the Key Outcomes for Productivity in the UK?

Proper glove matching directly enhances productivity by minimising downtime caused by chemical exposure incidents. When employees are equipped with appropriate materials, they can perform their tasks with greater confidence and efficiency. Insights from local industry practices indicate that organisations prioritising effective glove selection experience fewer interruptions due to injuries or safety violations. This ultimately contributes to a more engaged workforce and improved overall productivity. By reducing exposure risks and enhancing safety, workplaces can cultivate an environment that supports both health and performance, driving success for the entire organisation.

Best Practices for Selecting Gloves in the UK

Why Routine Assessment of Chemical Needs Is Essential

Regular reviews of the chemicals handled in UK workplaces are critical for optimal glove selection. Employers should conduct routine assessments to identify any shifts in chemical use or the introduction of new substances into the work environment. Selecting materials that align with local exposure limits ensures workers are adequately protected against potential hazards. This proactive approach not only enhances safety but also signifies a commitment to regulatory compliance. By staying informed about evolving chemical requirements, organisations can make informed decisions about glove materials, ultimately safeguarding their workforce.

How Can Training Programmes Benefit UK Personnel?

Implementing education and training programmes focused on material matching is fundamental for fostering awareness among UK personnel. These programmes should emphasise the importance of selecting the correct gloves for specific chemicals, highlighting the potential risks associated with mismatched materials. Regular training sessions equip employees with the knowledge and skills necessary to handle chemicals safely and effectively. By promoting a culture of safety and compliance, organisations empower their workforce to make informed decisions regarding personal protective equipment, ultimately enhancing workplace safety.

Why Is Updating Glove Inventories Crucial in the UK?

Maintaining up-to-date glove inventories is vital for ensuring that protective materials meet current UK standards. As chemical use evolves and new regulations are introduced, organisations must adjust their glove stocks accordingly. Regularly reviewing and updating glove inventories helps ensure that employees have access to compliant materials that offer adequate protection. This practice not only enhances safety but also mitigates risks associated with outdated or ineffective gloves. By prioritising inventory management, organisations can adopt a proactive approach to workplace safety.

How to Ensure Compliance with UK Regulations?

Regular verification of glove selections against current British health and safety standards, such as those set by the Health and Safety Executive, is essential for mitigating risks. Employers must stay informed about regulatory changes and ensure their glove materials comply with these standards. This ongoing diligence helps protect workers from chemical exposures and reinforces a culture of safety within the organisation. By prioritising compliance, companies can enhance their reputations and demonstrate their commitment to employee health and safety.

What Are the Effective Strategies for Proper Glove Storage and Maintenance?

Implementing effective storage methods for gloves in accordance with UK guidelines is crucial to preventing degradation and maintaining their protective integrity. Gloves should be stored in cool, dry environments to maintain their performance over time. Routine maintenance checks are vital, allowing organisations to identify any signs of wear or damage before gloves are deployed. Training personnel on proper glove storage and maintenance practices can significantly extend the lifespan of protective equipment. By prioritising these practices, organisations enhance the effectiveness of their personal protective equipment and ensure ongoing protection for their workforce.

Frequently Asked Questions

What Are the Most Common Glove Materials Used in the UK?

The most common glove materials used in the UK include nitrile, latex, PVC, and vinyl, each selected for its compatibility with specific chemicals and resistance to various hazards.

How Can I Determine the Right Glove for a Specific Chemical?

To determine the correct gloves for a specific chemical, consult material compatibility charts and perform risk assessments, ensuring the chosen gloves provide adequate protection against the chemicals being handled.

What Standards Should Gloves Comply With in the UK?

Gloves in the UK should adhere to standards such as BS EN 374 for chemical resistance and BS EN 420 for general requirements, ensuring they meet essential safety and performance criteria.

How Often Should Glove Inventories Be Updated?

Glove inventories should be updated regularly, ideally quarterly or when new chemicals are introduced, to ensure compliance with current safety standards and reflect any changes in chemical usage.

What Training Is Necessary for Proper Glove Material Selection?

Employees should receive training on material compatibility, proper glove use, and chemical-handling techniques to ensure they understand the importance of selecting the right gloves for their tasks.

What Are the Dangers of Using Mismatched Gloves?

Mismatched gloves can lead to chemical exposure, skin irritation, and serious health issues, underscoring the critical importance of proper material selection for workplace safety.

How Do Environmental Factors Affect Glove Performance?

Environmental factors such as temperature and humidity can affect the integrity of glove materials, thereby influencing their resistance to chemicals and overall effectiveness, necessitating careful consideration during selection.

Are There Gloves Specifically Designed for Food Handling?

Yes, there are gloves specifically designed for food handling, often crafted from materials such as latex or polyethene, which comply with food safety standards to prevent contamination.

How Can Organisations Ensure Compliance with Regulations?

Organisations can ensure compliance by consistently reviewing and updating glove selections in line with the latest health and safety regulations and by providing employees with training on proper glove use.

What Innovations Are Available in Glove Materials?

Recent innovations in glove materials include bio-based polymers and enhanced synthetic materials that offer improved durability, flexibility, and chemical resistance, addressing the evolving needs of various industries.

Add comment